Gas System Shift

Gas System for tracking chambers

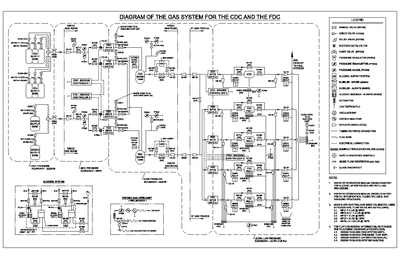

The gas system provides the operating gas mixtures for the two tracking detectors FDC and CDC. The two detectors have to independent mixing stations to provide the appropriate gas mixture for the detectors. In case of the FDC this is a 40%/50% Argon/CO2 gas mixture while for the CDC it is a 50%/50% Argon/CO2 mixture. The gas is provided by high pressure (2500psi Argon, 800psi CO2) gas bottles located outside the gas shed (room 401 building 202). The gas pressure is regulated down to 50psi and directed into the gas shed. The gas mixing is done using a BROOKS mass flow controllers for each gas type. The gas is filled into a blending tank from which the gas is enriched with propyl alcohol before it is sent to the upper platform in the hall. The pressure in the blending tank is controlled by the PLC system and keept between 7 and 12 psi.

The gas is distributed to the FDC and CDC through mass flow controllers located on the gas panel on the upper platform in the hall. Mineral oil bubblers on the upstream end of the detector (should never bubble) protect the detector from over pressure while the bubblers at the detector exhaust (should always bubble) protect the chambers from back flow.