Beam Test Run Plan

Contents

General

Beam Request Document (GlueX-doc-620): Media:Bcal_test.pdf

The task of BCAL is to measure the positions and energies of photons emitted from interactions in the GlueX target from 10-117 degrees with respect to the beam direction. The photon position resolution of BCAL is determined by the time resolution. The timing information from BCAL will also be used to determine the time-of-flight information for charged particles entering BCAL after passing through layers of straw drift tubes (central drift chamber - CDC) surrounding the target.

Scope and Objectives

This is the summary of our test-beam goals for one week of beam time (Sep. 22-30, 2006) delivered to Hall-B during the period in 2006 when the CEBAF accelerator is running at 687 MeV. The electron beam will produce a photon beam using the Hall-B tagger system. Photons of various energies will be used to measure the response of a 4-m-long lead, scintillating fiber (Pb/SciFi) prototype module for the GlueX barrel calorimeter (BCAL). The 687 MeV endpoint energy will provide the minimum photon energies needed for these tests. The module will be mounted on a support system in the Hall-B alcove area. The module will be illuminated at several positions along its length and at several angles, from 0-80 degrees with respect to normal incidence. The data will be anchored to results obtained using cosmic rays and will allow us to measure energy resolution, time resolution and linearity and will also allow a validation of our Monte Carlo simulations.

Goals

- Measure the energy resolution of the center of the module at normal incidence and also determine the linearity over the range of photon energies from 137 to 653 MeV (see Table 1).

- Measure the timing resolution at the center of the module at normal incidence.

- Repeat the above energy and timing resolution measurements at the center of the module for four angles of incidence at and between 45-80 degrees.

- Repeat the above energy and timing resolution measurements at normal incidence and at four angles of incidence at and between 45-80 degrees for four positions from the center to the end of the module.

Prototype Module (Module 1)

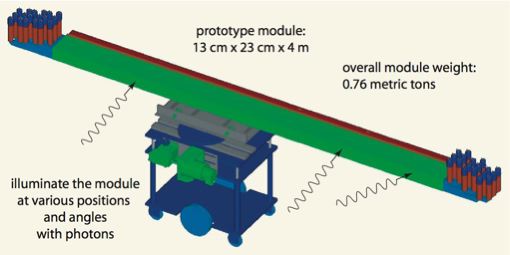

A 4~m-long prototype module, termed Module 1 was constructed in 2004 and this will be tested in the 2006 Test Beam at Hall-B. The module, shown schematically in the figure below, has a rectangular cross section of 13 x 23.0 cm^2 active area of Pb/SciFi. Over 70 km of double-clad fiber and 12 kg of epoxy were used in its construction. The scintillating fibers were made by PolHiTech and are blue-emitting with a peak emission wavelength of 420 nm and an attenuation length of ~350 cm. The fibers have a diameter of 1 mm (with 3% and 1% being the thickness of the first/inner and second/outer cladding layers) and the thickness of the lead sheets is 0.5 mm. The module has 186 planes of Pb/SciFi. The composite has a Pb:SciFi:Epoxy ratio of 37:49:14 and an overall density of ~ 5 gm/cm^3 and a radiation length (X_0) of 1.5 cm. Each layer of the module to be tested has 96 SciFi's spaced 1.38 mm apart (center-to-center) and the layers are such that they do not present any gaps in SciFi coverage thus presenting a uniform SciFi density across the shower path. The total weight of the module is 760 kg (including associated aluminum and steel plates) and the support carriage weighs an additional 550 kg. The former rests on top of the latter and both are supported by a cart that has a motorized, computer-driven, remote-controlled turn table.

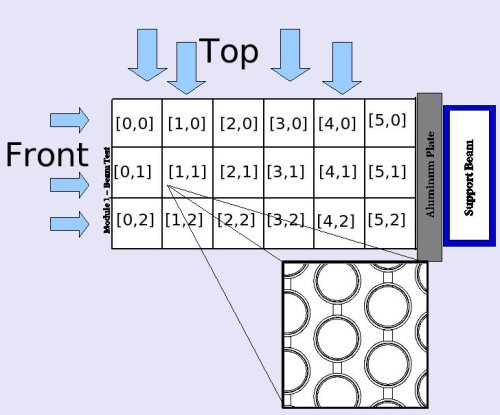

For purposes of the beam tests, the readout will be based on a segmentation scheme of 3 x 6 light guides, each with a cross section of 4 x 4 cm^2, for a total of 36 channels. The channels are grouped in six (0-5) layers (depth, as the beam sees it) and three sectors (0-2) (width). The PMTs are Philips XP2020 (layers 0-2, front nine on each side - 18 in total) and Burle 8575 (layers 3-5, back nine on each side - 18 in total). This segmentation has been studied via Monte Carlo simulations of the detector and is shown schematically below. The choice of phototube is based on providing the best timing measurement and this is why the XP2020 are mounted on the front half of the Module, where the energy deposition is greatest. The detailed labelling of the PMTs and cables will be indicated in the GlueX E-Log and will be based on Hall-B orientation into North (right - as the particle travels) and South (left) ends.

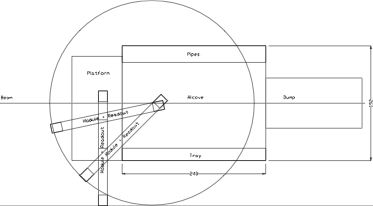

Module Positioning and Rotation

The figure below schematically shows the 4~m-long BCAL module in several positions in the Hall-B alcove needed to achieve the beam test goals. The carriage and cart position the module so that the beam can enter at any point along the face of the module. The angle of incidence (with respect to normal) can be set between 0-45 degrees when on the platform and 45-60 when in the alcove (Eric check). The platform in front of the alcove has been modified for this setup and a steel plate has been installed as flooring: it stradles the platform and alcove.

Calibrations/Checks with Cosmics

The initial calibration of the BCAL prototype module (Module 1) will be accomplished using cosmics...

Trigger/DAQ Tests

PMT Checks

PMT Gain Matching

Cosmics Runs

Pedestals and timing offsets can be determined using cosmics...

Calibrations/Checks with Beam

Trigger and Commissioning

PMT Checks

PMT Gain Matching

===DAQ Monitoring Histograms

Test Beam

Hall-B and Tagger

| Photon Energy (MeV) | Fraction of electrons through magnet | Fraction of photons through collimator |

| 653 | 0.872 | 0.067 |

| 618 | 0.934 | 0.066 |

| 550 | 0.961 | 0.066 |

| 344 | 0.977 | 0.070 |

| 137 | 0.983 | 0.072 |

| Table 1: Hall-B Tagger characteristics at an endpoint energy of 687 MeV | ||

During the initial stages of beam in Hall-B, the BCAL will be positioned so that the beam impacts at its center, and at a 90 degree angle...

Priority Goals

Secondary Goals

Sample Histograms

Sample histograms of expected energy deposition in the readout cells of the BCAL Module will be continuously updated on the Wiki.

Safety Documents

Procedures

...work in progress, hope for a draft by August 26 -- zp