Forward Drift Chamber Shift

The Forward Drift Chambers

The Forward Drift Chamber (FDC) system consists of four identical packages (named FDC1 to FDC4), each having six chambers or cells (named CELL1 to CELL6). These are planar drift chambers with both anode wires and cathode strips being readout, in total 12,672 channels.

The cells within a package have independent gas volumes, but are separated with a flexible mylar membrane and therefore the pressure difference between neighboring cells should never exceed 30Pa and should normally be less than 5Pa.

Positive (up to 2200V) and negative (up to 500V) HV is applied on the sense and field wires respectively with dark currents not exceeding 3 microA per HV channel .

The detector (including cables) emits a total power of about 1500~Watt, of which about 900~Watt inside the magnet, due to the LV applied on the detector pre-amplifieres. A cooling system using Fluorinert is used to keep the temperature on the pre-amplifiers within the permissible limits. The LV system should never be turned ON if the cooling system doesn't work .

Routine operation

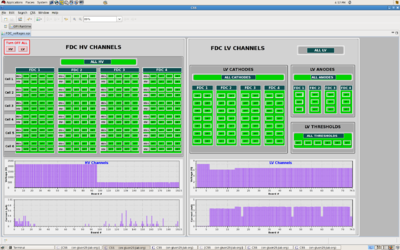

The most important task for the shift workers is to monitor the parameters (using GUIs) and report any changes from the normal operation for the following FDC related subsystems: High Voltage, Low Voltage (including thresholds), Gas system, and the Cooling system. A description of how to bring up the corresponding GUI screens and how to operate them can be found in Section Slow Controls. The HV and LV subsystems, as well as and the Gas and Cooling systems have common GUIs. The GUIs are designed to show green color if all the parameters in a certain subsystem/subgroup are within the limits. If any of the parameters is out of limits the background for the corresponding subsystem/subgroup will turn red. Examples of the GUIs are shown in Figs. 1 and 2.

The shift workers are allowed, using the GUI, to turn ON and OFF all the HV and LV (including thresholds) systems, as well as parts of them or the individual channels. Instructions how to do this are given in Section Slow Controls, but the general rule is either to bring the pop-up menu with left click on the group title (like "ALL HV", or "FDC 1") or to click on the individual channel knob (the knob title shows the action to be taken after pressing it). For example, in case a HV channel trips, one should press the corresponding channel knob once (acknowledging the trip) and then again to turn it on. The corresponding voltage rump up/down rates as well as the set voltages cannot be changed by the shift workers. The Gas and cooling system GUI is only to be monitored by the shift workers, the parameters there cannot be changed.

Operations beyond what was specified above shall only be performed by the system expert or under his/her direction .