Difference between revisions of "Solenoid Ramping Shift"

(Created page with "== The Solenoid Magnet == The principle analysis magnet for the GlueX spectrometer is a superconducting solenoid made from the Large Aperture Solenoid Spectrometer (LASS) sol...") |

(→Setup) |

||

| (45 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | == Routine Operation == | ||

When powered with the maximum current of 1350 A, the solenoid generates a field close to 2 Tesla in the bore. | When powered with the maximum current of 1350 A, the solenoid generates a field close to 2 Tesla in the bore. | ||

The full inductance of the solenoid is about 26 H. | The full inductance of the solenoid is about 26 H. | ||

| − | + | As the superconducting solenoid is very complex system, the operation of such system requires considerable knowledge and experience. The commissioning, troubleshooting, tuning of ground fault and quench detectors, Power ON and OFF, change current will be conducted by authorized experts only. | |

| − | + | ||

| − | + | ||

| − | As the superconducting solenoid is very complex system, the operation of such system requires | + | |

The responsibilities of the shift workers include: | The responsibilities of the shift workers include: | ||

| Line 39: | Line 13: | ||

* Make log entries to the [https://logbooks.jlab.org/book/HDLOG HDLOG] and [https://logbooks.jlab.org/book/HDSOLENOID HDSOLENOID] logbooks. | * Make log entries to the [https://logbooks.jlab.org/book/HDLOG HDLOG] and [https://logbooks.jlab.org/book/HDSOLENOID HDSOLENOID] logbooks. | ||

| − | = | + | These procedures are documented in the [https://misportal.jlab.org/jlabDocs/document.seam?id=85132 Hall D Solenoid Normal Ramp up Procedure for Shift takers (D00000-04-02-P013)] . Additional information can be found in detailed [[Solenoid Operations | Operation Instructions]] and [[Solenoid_Expert | Expert Information]]. |

| − | == | + | == Ramping the Magnet == |

| + | [[Image:Solenoid Vacuum Status.png | thumb | 485px | Fig. 1. Solenoid vacuum status screen]] | ||

| + | [[Image:Solenoid status pickup coil.png | thumb | 485px | Fig. 2. Solenoid pickup coil status screen]] | ||

| + | [[Image:Solenoid status forces.png | thumb | 485px | Fig. 3. Solenoid strain gauges]] | ||

| − | + | '''This procedure is to be used by shift operators after all the preliminary checks have been completed and approval to ramp has been given by the Solenoid system expert.''' It assumes the magnet is at 0A current. The slew rates to ramp the magnet are defined in the state machine and are | |

| + | 0.2A/s up to 800A, 0.12A/s from 800 to 1000A and 0.06A/s after that. | ||

| − | |||

| − | # | + | === Setup === |

| − | # | + | # Pull up CSS Solenoid screens as follows: |

| − | # | + | #* Pull up Solenoid Control screen from CSS main screen - Magnet/Solenoid |

| − | # | + | #* Cryo System (from Solenoid Control screen) |

| − | # | + | #* Interlock |

| − | # | + | #* Power Supply |

| − | # | + | #* Voltage Taps/PXI |

| + | #* Vacuum Pumps | ||

| + | #* Strain Gauges | ||

| + | # From the “Voltage Taps/PXI fast DAQ" screen, do the following; | ||

| + | #* Click on the “Plot all Pickup Coils” button to open a Voltage vs. Time graph | ||

| + | #* Stop Recording Root File and Stop the PXI DAQ | ||

| + | #* Press the Calibrate button and wait until voltages zero out | ||

| + | #* Ensure the PXI DAQ is running (if not click “Start PXI DAQ” button | ||

| + | #* Click on “Start Recording ROOT File” button. Make sure “File Size” is increasing. | ||

| + | #* Click on the “Current” box at the top to start a Current vs. Time graph | ||

| + | # On the “Solenoid Strain Gauges” window: | ||

| + | #* Confirm magnet is at zero current. Click on the “Zero Strain Gauges” button (all strain gauges should read close to 0). | ||

| + | #* Click on “Plot All Forces” button (Graph for 4 coils should be displayed) | ||

| + | #* Close strain gauge window | ||

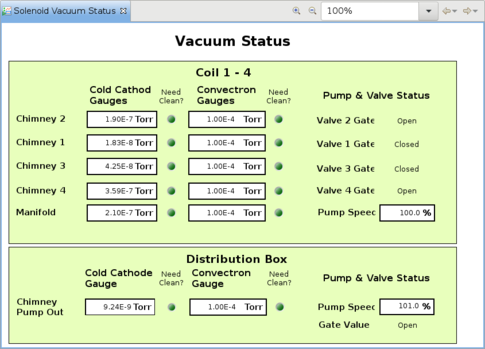

| + | # Ensure all is green on the “Vacuum Status” window and pumps are at 100% or better. The screen should look like in Fig. 1. | ||

| + | # On “Interlock Status” screen, all should be green except the Main Contactor which will be red until the MPS is turned on. If not, click on the “Reset Interlocks” button. | ||

| + | # Confirm Reset worked. If not, try again. If it still did not work, contact solenoid expert. | ||

| + | # Arrange all the screens so they are visible. | ||

| − | + | ===Ramp up=== | |

| − | |||

| − | + | # On “MPS Auto Control” screen, all should be green except “MPS On” box. If not, click on the “Reset MPS” button. | |

| + | # Confirm Reset (all boxes except “MPS On” are green). | ||

| + | # Set current in “Final Goal” box to 0 (zero) and hit enter. | ||

| + | # Confirm 0 (zero) reading in “Final Goal” box. | ||

| + | # Click on the “Turn On MPS” button. Confirm all boxes are green. | ||

| + | # Confirm MPS is on (all boxes green). | ||

| + | # Set desired current in the “Final Goal” box. | ||

| + | # Click on the ramp button. Note: the ramps are programmed into the system and will soak at 800A for 15 minutes, 1000A for 1 hr and 1200A for 1 hr | ||

| + | # Confirm magnet is ramping by seeing an increase in current. | ||

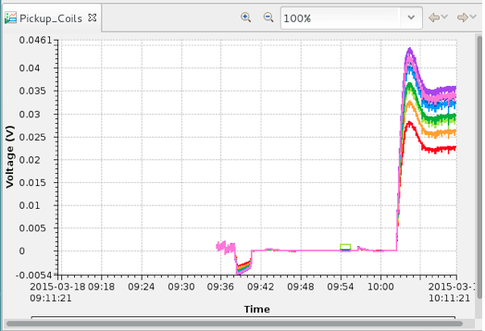

| + | # Pay close attention to the “Pick Up Coil” and “Strain Gauge” graphs to ensure the signals are acting normally (see Figs. 2 and 3). If not, click on the “Cancel” button and notify solenoid expert. | ||

| + | # When the current is at approximately 40A, take a screen shot of all the windows and post an HDLOG and HDSOLENOID log. | ||

| + | #* Press Alt+Prt Scrn | ||

| + | #* Either pick “current window” or “all windows” (if you pick current window, only the active window will be used and you must repeat for all windows) and click ok | ||

| + | #* Add “solenoid ramp” (or specific window) to the name of the file after the date and save. The correct folder is hdops/pictures/solenoid screenshots and pictures. | ||

| + | #* Make an HDLOG/HDSOLENOID entry and attach screenshots | ||

| + | # If there is a dump, ensure an HDLOG is made with a current screen shot and contact mechanical on call. Do not reset anything until instructed to do so. | ||

| + | # If a ramp is cancelled/stopped for any reason and the system expert gives the ok to continue ramping, type in the new “Final goal” set point and click the ramp button. | ||

| − | + | ===Ramp down=== | |

| − | + | # To ramp down to zero current, type in “0” as the “Final Goal” and click the ramp button. | |

| + | # Take screenshots of any relevant windows, especially if there are any anomalies during rampdown. | ||

| − | == | + | == When the Solenoid Trips == |

| − | + | * Call Mechanical On-Call (757-544-7258) every time when the power supply trips! | |

| − | + | * DO NOT clear interlock status or attempt to change MPS state before the Solenoid On-Call responses! | |

| + | * Make screen shots of Solenoid status and post them to the [https://logbooks.jlab.org/book/HDLOG HDLOG] and [https://logbooks.jlab.org/book/HDSOLENOID HDSOLENOID] logbooks: Interlock, MPS, Voltage, Cryo, Vacuum, Strain Gauge. | ||

| − | |||

| − | + | == PXI DATA Monitoring == | |

| + | There are two applications that allow you to view the PXI data "analyzer" and "pximon". | ||

| − | === | + | === PXI Data Analyzer === |

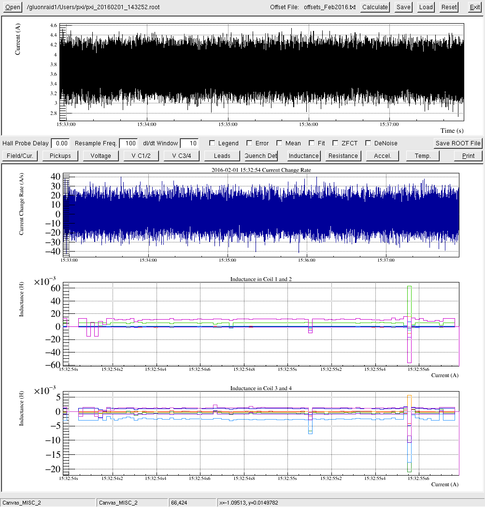

| + | The main diagnostics tool to view all PXI voltage tabs is called "analyzer". It can be started directly from the PXI volage tabs GUI clicking on the button "Analyzer" or by going to the directory "/home/hdops/solenoid/" and type in there "./analyzer". Using this GUI you can open any PXI data file that contains all data of the voltage tabbs, pick-up coils and accelerometers at a 10kHz sample rate (see fig. 1). | ||

| + | [[Image:AnalyzerPXIdata.png | thumb | 485px | Fig. 1. PXI Data Analyzer]] | ||

| − | + | === Accelerometer Monitor === | |

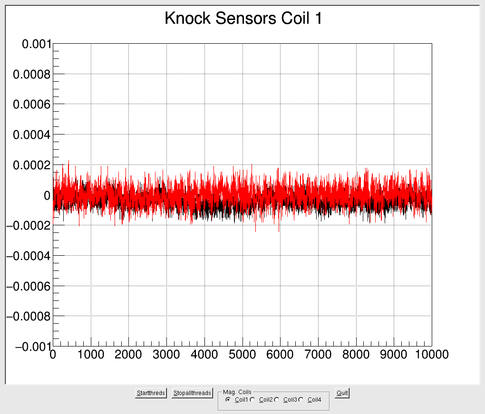

| + | To monitor the accelerometeres start the program in "/home/hdops/solenoid" with the command "./pximon_1". This will start up a GUI in which you will click the button "Startthreads". This will show the accelerometer data for each coil separately that the user can select with the raido buttons at the bottom of the GUI. (see fig. 2) | ||

| + | [[Image:accelerometerMonitor.png | thumb | 485px | Fig. 2. Accelerometer Monitor]] | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Expert personnel == | == Expert personnel == | ||

| Line 167: | Line 104: | ||

! width=200px | Name !! width=100px | Extension !! width=100px | Cellphone !! width=100px | Pager !! Date of qualification | ! width=200px | Name !! width=100px | Extension !! width=100px | Cellphone !! width=100px | Pager !! Date of qualification | ||

|- | |- | ||

| − | | Mechanical On-Call || align=center | || align=center | 544-7258 || align=center | || align=center | | + | | Mechanical On-Call || align=center | || align=center | 544-7258 || align=center | || align=center | Sept 19, 2017 |

|- | |- | ||

| − | | | + | | Tim Whitlatch- Solenoid || align=center | 269-5087 || align=center | 876-1766 || align=center | [mailto:whitey-page@jlab.org] || align=center | Sept 19, 2017 |

|- | |- | ||

| − | | | + | | Beni Zihlmann - Solenoid/PXI || align=center | 269-5310 || align=center | 926-9671 || align=center | [mailto:zihlmann-page@jlab.org] || align=center | Sept 19, 2017 |

|- | |- | ||

| − | | Mark Stevens - Power Supply || align=center | 269-6383 || align=center | | + | | Mark Stevens - Power Supply || align=center | 269-6383 || align=center | 310-1576 || align=center | [mailto:stevensm-page@jlab.org] || align=center | Sept 19, 2017 |

|- | |- | ||

| − | | Scot Spiegel - MPS/Solenoid || align=center | || align=center | 536-5900 || align=center | [mailto:spiegel-page@jlab.org] || align=center | | + | | Scot Spiegel - MPS/Solenoid || align=center | 269-5900|| align=center | 536-5900 || align=center | [mailto:spiegel-page@jlab.org] || align=center | Sept 19, 2017 |

|- | |- | ||

| − | | | + | | Chris Perry - Cryogenics || align=center | 269-6157|| align=center | 371-4926 || align=center | [mailto:creel-page@jlab.org] || align=center | Sept 19, 2017 |

|- | |- | ||

| − | | | + | | Jonathan Creel - Cryogenics || align=center | 269-5925|| align=center | 869-8910 || align=center | [mailto:creel-page@jlab.org] || align=center | Sept 19, 2017 |

|- | |- | ||

| − | |||

| − | |||

| − | == | + | | Nick Sandoval - PLC || align=center | 269-6506 || align=center | (540) 907-2637 || align=center | [mailto:butler-page@jlab.org] || align=center | Sept 19, 2017 |

| + | |- | ||

| + | | Carroll Jones - LCW || align=center | 876-1778 || align=center | 876-1778 || align=center | [mailto:jonesc-page@jlab.org] || align=center | Sept 19, 2017 | ||

| + | |} | ||

Revision as of 08:49, 9 December 2019

Contents

Routine Operation

When powered with the maximum current of 1350 A, the solenoid generates a field close to 2 Tesla in the bore. The full inductance of the solenoid is about 26 H. As the superconducting solenoid is very complex system, the operation of such system requires considerable knowledge and experience. The commissioning, troubleshooting, tuning of ground fault and quench detectors, Power ON and OFF, change current will be conducted by authorized experts only.

The responsibilities of the shift workers include:

- Monitor the overall status of the solenoid: current, field, interlocks, voltages, cryogenic levels etc.

- Notify experts when anomalies happen.

- Ramp the magnet per request of run coordinator.

- Make log entries to the HDLOG and HDSOLENOID logbooks.

These procedures are documented in the Hall D Solenoid Normal Ramp up Procedure for Shift takers (D00000-04-02-P013) . Additional information can be found in detailed Operation Instructions and Expert Information.

Ramping the Magnet

This procedure is to be used by shift operators after all the preliminary checks have been completed and approval to ramp has been given by the Solenoid system expert. It assumes the magnet is at 0A current. The slew rates to ramp the magnet are defined in the state machine and are 0.2A/s up to 800A, 0.12A/s from 800 to 1000A and 0.06A/s after that.

Setup

- Pull up CSS Solenoid screens as follows:

- Pull up Solenoid Control screen from CSS main screen - Magnet/Solenoid

- Cryo System (from Solenoid Control screen)

- Interlock

- Power Supply

- Voltage Taps/PXI

- Vacuum Pumps

- Strain Gauges

- From the “Voltage Taps/PXI fast DAQ" screen, do the following;

- Click on the “Plot all Pickup Coils” button to open a Voltage vs. Time graph

- Stop Recording Root File and Stop the PXI DAQ

- Press the Calibrate button and wait until voltages zero out

- Ensure the PXI DAQ is running (if not click “Start PXI DAQ” button

- Click on “Start Recording ROOT File” button. Make sure “File Size” is increasing.

- Click on the “Current” box at the top to start a Current vs. Time graph

- On the “Solenoid Strain Gauges” window:

- Confirm magnet is at zero current. Click on the “Zero Strain Gauges” button (all strain gauges should read close to 0).

- Click on “Plot All Forces” button (Graph for 4 coils should be displayed)

- Close strain gauge window

- Ensure all is green on the “Vacuum Status” window and pumps are at 100% or better. The screen should look like in Fig. 1.

- On “Interlock Status” screen, all should be green except the Main Contactor which will be red until the MPS is turned on. If not, click on the “Reset Interlocks” button.

- Confirm Reset worked. If not, try again. If it still did not work, contact solenoid expert.

- Arrange all the screens so they are visible.

Ramp up

- On “MPS Auto Control” screen, all should be green except “MPS On” box. If not, click on the “Reset MPS” button.

- Confirm Reset (all boxes except “MPS On” are green).

- Set current in “Final Goal” box to 0 (zero) and hit enter.

- Confirm 0 (zero) reading in “Final Goal” box.

- Click on the “Turn On MPS” button. Confirm all boxes are green.

- Confirm MPS is on (all boxes green).

- Set desired current in the “Final Goal” box.

- Click on the ramp button. Note: the ramps are programmed into the system and will soak at 800A for 15 minutes, 1000A for 1 hr and 1200A for 1 hr

- Confirm magnet is ramping by seeing an increase in current.

- Pay close attention to the “Pick Up Coil” and “Strain Gauge” graphs to ensure the signals are acting normally (see Figs. 2 and 3). If not, click on the “Cancel” button and notify solenoid expert.

- When the current is at approximately 40A, take a screen shot of all the windows and post an HDLOG and HDSOLENOID log.

- Press Alt+Prt Scrn

- Either pick “current window” or “all windows” (if you pick current window, only the active window will be used and you must repeat for all windows) and click ok

- Add “solenoid ramp” (or specific window) to the name of the file after the date and save. The correct folder is hdops/pictures/solenoid screenshots and pictures.

- Make an HDLOG/HDSOLENOID entry and attach screenshots

- If there is a dump, ensure an HDLOG is made with a current screen shot and contact mechanical on call. Do not reset anything until instructed to do so.

- If a ramp is cancelled/stopped for any reason and the system expert gives the ok to continue ramping, type in the new “Final goal” set point and click the ramp button.

Ramp down

- To ramp down to zero current, type in “0” as the “Final Goal” and click the ramp button.

- Take screenshots of any relevant windows, especially if there are any anomalies during rampdown.

When the Solenoid Trips

- Call Mechanical On-Call (757-544-7258) every time when the power supply trips!

- DO NOT clear interlock status or attempt to change MPS state before the Solenoid On-Call responses!

- Make screen shots of Solenoid status and post them to the HDLOG and HDSOLENOID logbooks: Interlock, MPS, Voltage, Cryo, Vacuum, Strain Gauge.

PXI DATA Monitoring

There are two applications that allow you to view the PXI data "analyzer" and "pximon".

PXI Data Analyzer

The main diagnostics tool to view all PXI voltage tabs is called "analyzer". It can be started directly from the PXI volage tabs GUI clicking on the button "Analyzer" or by going to the directory "/home/hdops/solenoid/" and type in there "./analyzer". Using this GUI you can open any PXI data file that contains all data of the voltage tabbs, pick-up coils and accelerometers at a 10kHz sample rate (see fig. 1).

Accelerometer Monitor

To monitor the accelerometeres start the program in "/home/hdops/solenoid" with the command "./pximon_1". This will start up a GUI in which you will click the button "Startthreads". This will show the accelerometer data for each coil separately that the user can select with the raido buttons at the bottom of the GUI. (see fig. 2)

Expert personnel

The individuals responsible for checking that the solenoid is ready to take data and setting its operating parameters are shown in following table. Problems with normal operation of the solenoid should be referred to those individuals and any changes to their settings must be approved by them. Additional experts may be trained by the system owner and their name and date added to this table.

| Name | Extension | Cellphone | Pager | Date of qualification |

|---|---|---|---|---|

| Mechanical On-Call | 544-7258 | Sept 19, 2017 | ||

| Tim Whitlatch- Solenoid | 269-5087 | 876-1766 | [1] | Sept 19, 2017 |

| Beni Zihlmann - Solenoid/PXI | 269-5310 | 926-9671 | [2] | Sept 19, 2017 |

| Mark Stevens - Power Supply | 269-6383 | 310-1576 | [3] | Sept 19, 2017 |

| Scot Spiegel - MPS/Solenoid | 269-5900 | 536-5900 | [4] | Sept 19, 2017 |

| Chris Perry - Cryogenics | 269-6157 | 371-4926 | [5] | Sept 19, 2017 |

| Jonathan Creel - Cryogenics | 269-5925 | 869-8910 | [6] | Sept 19, 2017 |

| Nick Sandoval - PLC | 269-6506 | (540) 907-2637 | [7] | Sept 19, 2017 |

| Carroll Jones - LCW | 876-1778 | 876-1778 | [8] | Sept 19, 2017 |