February 16, 2011 Tracking CDC/FDC

From GlueXWiki

Meeting Time and Place

Wednesday February 16, 2011 at 11:00am At Jefferson Lab, the meeting will be held in F326

Connections

To connect from the outside, please use ESNET

- ) ESNET: 8542553

- )To connect by telephone, dial:

- You can look up toll-free number at http://www.readytalk.com/intl

- US and Canada: (866)740-1260 (toll free)

- International: (303)248-0285 (toll call)

- enter access code followed by the # sign: 3421244#

Agenda

- Announcements

- FDC Update logbook

- CDC Update

- Log of Construction Complications

- Recent CDC Photos

-

Construction status

Construction status

Minutes

Participants: Curtis, Naomi, Beni, Lubomir, Simon, Dave, Mark, Tim and Elton.

FDC Update

- All the stuff needed has been moved to Blue Crab, except the wire stringing system.

- The first (test) wire plane strung at JLab is ready. Results from position and tension measurements are shown on page 550 of the FDC logbook. On the top plot: deviation from the nominal position vs nominal wire position. Two features are visible there: 1)overall slope 2)offset in the middle of the chamber of ~140microns. The overall slope is a result of the pitch being 3 mcirons off the nominal 5mm. Direct measurements of the pin positions in the middle of the chamber explained the wire position offset: one pitch only on one side of the wires is off by ~250microns.

- Based on our experience we are implementing now changes to the stringing system:

- Cutting the pin jig at the place with the wrong pitch and re-aligning it to compensate for the extra offset.

- Adding protective cover over the wires.

- Mounting monuments to be used to align the strongback with the pin positions.

- We received the conductive epoxy samples from CMU but have not tried them yet.

- Elton asked how did the wire soldering work. Lubomir: relatively easy operation, but different people did it with different quality checked with a camera. It was tricky to cut the wires without leaving the tip above the solder. Twisting was not always working; the best way was to rotate the wire to brake it.

CDC Update

- Curtis reported on the status of the CDC construction.

- Layer 13 was completed last week and layer 14 is being installed this week. Layers 13-16 are axial layers, which are a little easier to install than the stereo layers. Installation is going smoothly.

- The weather has started to thaw a little in Pittsburgh, but we have not noticed any change in the particulate levels in our clean room. We remain around class 2000. We also have been trying to raise the humidity in the room. This has reduced somewhat the static charge, but humidity remains around 22%. We anticipate that this will start to rise as we warm up this week.

- CMU has purchased an automatic wire stripper to start start building the CDC wires to connect the chamber wires to the HVBs. A sample was shown at the meeting. We are waiting on an order of wire and we have been working on jigs to assemble 25 wires at one. The jig will also facilitate making very consistent solder balls on the ends of the wires.

- The plan is to fully produce the wires on the bench in 1/4-inch length increments from about 3 inches to about 5 inches. We believe that most will be in the 3.5 to 4.0 inch range. We will plan to color-code the length using colored heat-shrink tubing. This will also allow us to know the exact length of each hookup wire.

- As requested, a wiki-based log of the construction complications with the CDC has been started. It is linked from the CDC main page under the Construction Sub menu. Tim noted that we need a final sign-off by Jefferson Lab. Beni will send an email to the tracking group which will be linked to the log as the final sign off.

- Naomi received the re calibrated MKS units back yesterday. She hopes to put those back in today or tomorrow.

- Naomi updated and completed the assembly procedure through installing straw tubes in the frame. If needed, the packet of procedures through that level could be signed-off on. All procedures after this are still subject to improvement once we start that part of the project.

- Naomi asked Tim if Slava could identify the longest connect length from the CDC to the HVB. Tim thought that he could easily do that and would ask him.

- Tim reported on communications with Lamina and said that he had identified a foil vendor (Shedahl) in the U.S. He has sent that information to Lamina and is trying to get price information from Lamina.

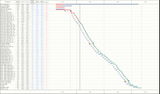

- Beni presented an updated CDC schedule based on the monthly reports from CMU. It looks like things have slipped (due to late start up) by about 1.5 months, but the current progress is now moving slightly ahead of schedule and CMU is trying to develop procedures to speed up the later parts of the project.