Difference between revisions of "Construction of Low-Granularity counters"

(→Assembly) |

(→Assembly) |

||

| Line 217: | Line 217: | ||

==Assembly== | ==Assembly== | ||

| − | Once done gluing, wrapping and testing, sensitive parts of the detector (i.e. the PMTs) will be wrapped in a Mu-metal foil which will ensure complete magnetic shielding coverage. Then it will be placed in a Mu-metal casing | + | Once done gluing, wrapping and testing, sensitive parts of the detector (i.e. the PMTs) will be wrapped in a Mu-metal foil which will ensure complete magnetic shielding coverage. Then it will be placed in a Mu-metal casing, held in place by a plastic collar, and sealed on the other end with a Mu-metal end cap and mounting plate. This assembly will serve as the PMT's primary magnetic shielding as well as a convenient way to mount the detectors in the hall. Once fully assembled, only the wrapped scintillator, part of the Light Guide, and connecting wires from the PMT will be exposed beyond the Mu-metal casing. |

==Installation== | ==Installation== | ||

Revision as of 10:30, 15 July 2013

Contents

[hide]PMT Testing

Expectations

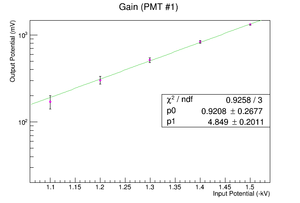

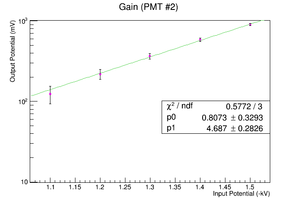

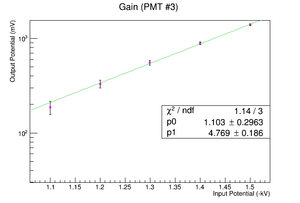

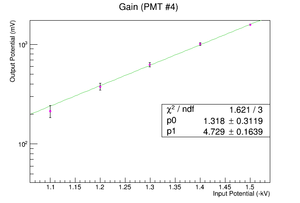

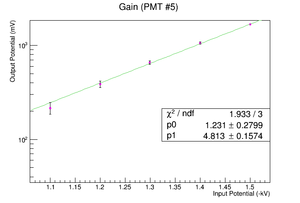

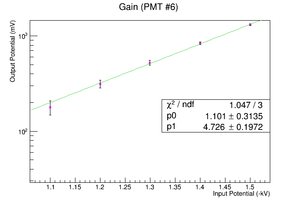

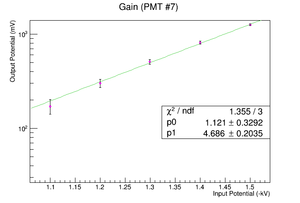

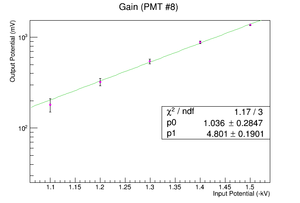

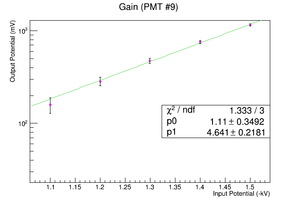

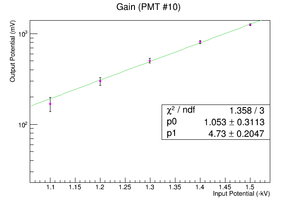

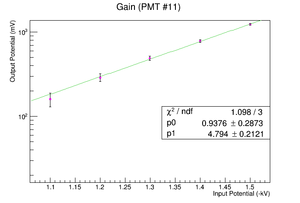

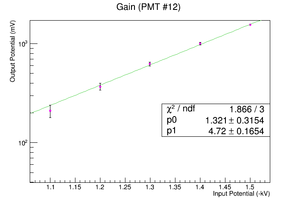

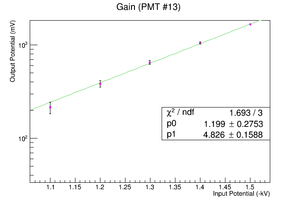

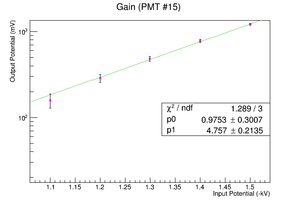

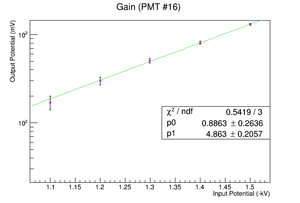

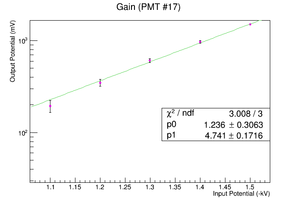

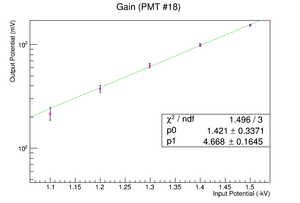

The photomultiplier tubes (i.e. 18 in all) should, in principle, all exhibit the same characteristics. All 18 should have the same change in output amplitude with a change in input potential, as well as identical time responses regardless of the input potential. Therefore, one would expect a histogram of these characteristics to show a count of 18 at a single value on the x-axis. Consequently, a logarithmic plot of the overall gains of each PMT should be 18 identical lines of positive slope.

The Hamamatsu Photomultiplier Tube (H7415) was chosen because it has the characteristics required for this pair spectrometer. This PMT will be attached to the EJ-200 organic plastic scintillator and light guide fabricated by Eljen Technology. The properties of the tube are in the table below:

| Photomultiplier Tube Assembly (H7415) | |

| Dynode Structure | Linear-focused |

| Dynode Stages | 10 |

| Max. Rating) Anode to Cathode Voltage | -2000 V |

| Anode to Cathode Supply Voltage | -1500 V |

| Anode) Gain Typ. | 5E+06 |

| (Time Response) Rise Time Typ. | 1.7 ns |

| (Time Response) Transit Time Typ. | 16 ns |

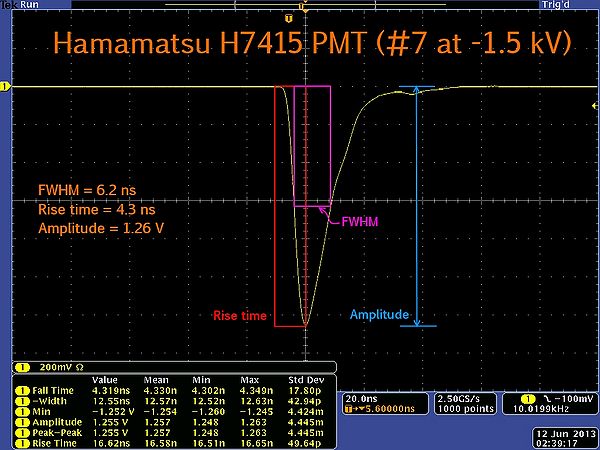

Rise time listed here was arrived at using a laser. In the testing of the PMT's at Jefferson Lab, an LED will be used, which will not produce a clean signal elimination like the laser.

Testing

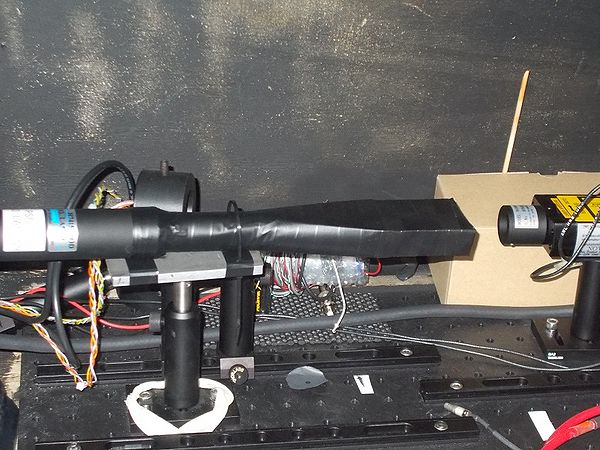

To test the PMT's, connections had to be soldered on to the wires in order to have quick connection ability to both the oscilloscope and high-voltage power source. Once this was done, the PMT was placed in a previously fabricated dark box with mounts for the tube and LED. The LED was powered by a wave generator which was set to run 8V square waves at 10 kHz with a 8 ns pulse width. Figure 1 shows the set up used for each PMT.

The LED was positioned behind a diffracted lens to spread the light out. Careful attention had to be made that each PMT was positioned at the same place on the mount in order to eliminate fluctuations in beam intensity. The anode-to-cathode potential would range from -1.1 kV to -1.5 kV.

Data

The data gathered from the oscilloscope were the amplitude and rise time. Figure 2 shows what those values represent on the oscilloscope screen. Amplitudes were measured in millivolts and the rise time was in nanoseconds.

The data for the PMT amplitudes is in the table below. At -1.1 kV, the minimum amplitude was 124 mV. At -1.5 kV, the maximum amplitude was 1660 mV.

| PMT Amplitudes (mV) | ||||||

|---|---|---|---|---|---|---|

| PMT # | -1.1 kV | -1.2 kV | -1.3 kV | -1.4 kV | -1.5 kV | |

| 1 | 171 | 303 | 513 | 833 | 1320 | |

| 2 | 124 | 219 | 365 | 583 | 906 | |

| 3 | 187 | 330 | 553 | 892 | 1400 | |

| 4 | 213 | 376 | 627 | 1010 | 1575 | |

| 5 | 216 | 387 | 657 | 1060 | 1670 | |

| 6 | 178 | 313 | 522 | 839 | 1310 | |

| 7 | 171 | 302 | 507 | 812 | 1256 | |

| 8 | 181 | 322 | 542 | 877 | 1380 | |

| 9 | 159 | 284 | 473 | 755 | 1160 | |

| 10 | 168 | 299 | 504 | 811 | 1260 | |

| 11 | 160 | 289 | 489 | 785 | 1236 | |

| 12 | 210 | 370 | 624 | 1000 | 1556 | |

| 13 | 214 | 385 | 650 | 1050 | 1660 | |

| 14 | 203 | 359 | 600 | 968 | 1500 | |

| 15 | 159 | 287 | 483 | 780 | 1215 | |

| 16 | 170 | 299 | 504 | 810 | 1300 | |

| 17 | 195 | 348 | 607 | 970 | 1500 | |

| 18 | 216 | 376 | 627 | 997 | 1550 | |

The data in the table above produced the plots located at the right side of the page.

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Conclusions

From the data gathered here, one can see that the original hope that all PMT's would behave identically must be abandoned. The histograms in Figure 3, Figure 4 and Figure 5 do not show a significant number of counts for any particular bin. However, the solution to this is simply to run the PMT's all at fixed anode-to-cathode potential. This would eliminate nearly all fluctuations between the various tubes. Finally, it should be noted that, like expected, the average rise times of the PMT's with an LED source is over twice the characteristic rise time of the device. This was what was expected. However, just to be sure, one PMT was tested with a laser and the rise time was 1.97 ns at -1.4 kV.

There were some sources of error that should be considered. The first is the soldering of connections. Every time testing of one device was complete, the connectors were unsoldered from the tested PMT and re-soldered to the untested PMT. Therefore, after being heated and cooled 36 times, there was bound to be some degradation after time. This was done to ensure that there were 16 brand new connectors for the final detectors. The other source of error was the distance from the PMT to the LED in the black box. Alignment was done visually and so there may have been small differences is distance between tests. This would have affected the intensity of light hitting the PMT.

Gluing

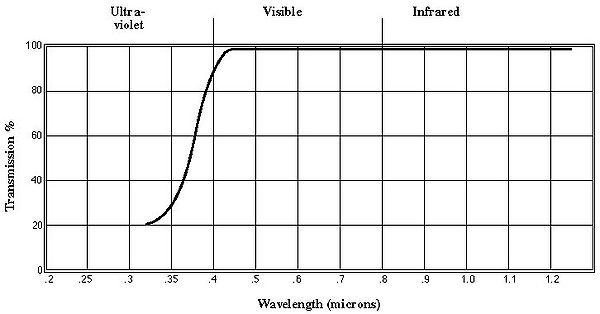

After some trial and error, the glue chosen was Norland Optical Adhesive 87. It is an adhesive that cures clear when exposed to ultraviolet light.

| Typical Properties of NOA 87 | |

|---|---|

| Refractive Index | 1.52 |

| Temperature Range | -30 C to 90 C |

| Viscosity @ 25C | 900-1500cps |

| Elongation at Failure | 13% |

| Modulus (PSI) | 209,700 |

| Tensile Strength | 4,880 |

| Hardness - Shore D | 50 |

Once the glue was chosen, testing could begin. The goal was to determine the minimal amount of glue necessary for complete covering of the surfaces as well as to determine the length of time the UV light was needed in order to cure properly.

Wrapping

Because we wish to minimize wrinkling, a custom template has been made. Using Mylar, the light guide was wrapped using a trial and error process. From the finalized wrapping a template was constructed from non-corrugated cardboard to make it more practical to use.

Once a template was completed, the light guide was wrapped with Mylar after being cleaned with distilled water and lent free cloth. Over the Mylar, a layer of Tedlar was added using the same template. The PS counter was then covered with a layer of black electrical tape and ready to be tested.

Cosmic Particle Detecting

Expectations

Because muons easily penetrate well into the Earth's surface, they will serve as a suitable means through which one can test a scintillator detector. Therefore, we hope to test these PS detectors in the same manner as we did with just the PMTs as outlined in Section 1. The difference will be that instead of the LED pulses, we will observe muon-interactions with the scintillator and amplified by the PMT. Each muon should, in theory, generate a readable pulse on the oscilloscope.

Testing

***Testing is currently ongoing. As more scintillator/light-guides are glued to the PMTs and wrapped, they will be tested for cosmics.***

The set up for the testing, as was previously stated, is very similar to the testing of the PMTs. The image below portrays how each PS detector will be situated in the dark box. The dark box is used, of course, to minimize the all outside sources of radiation in an attempt to isolate only the cosmic radiation we are looking for.

Data

***As more data is acquired, it will be posted.***

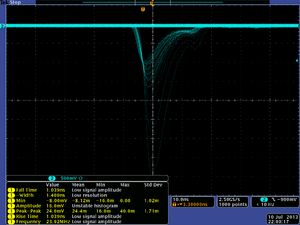

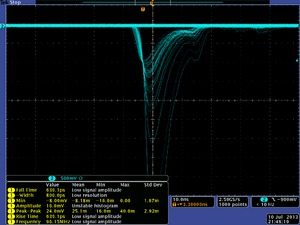

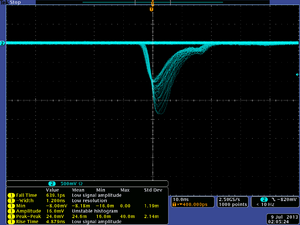

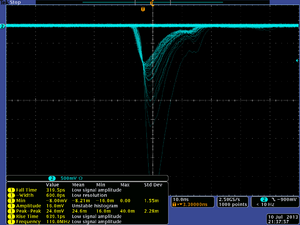

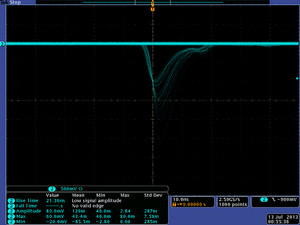

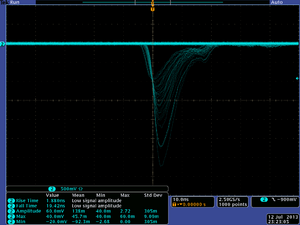

The PMT's that have been tested for cosmics are in Figures 11-13. The oscilloscope was set to keep a history of pervious pulses in an attempt to find an average pulse amplitude and the trigger in each was set to -900 mV.

Conclusions

Assembly

Once done gluing, wrapping and testing, sensitive parts of the detector (i.e. the PMTs) will be wrapped in a Mu-metal foil which will ensure complete magnetic shielding coverage. Then it will be placed in a Mu-metal casing, held in place by a plastic collar, and sealed on the other end with a Mu-metal end cap and mounting plate. This assembly will serve as the PMT's primary magnetic shielding as well as a convenient way to mount the detectors in the hall. Once fully assembled, only the wrapped scintillator, part of the Light Guide, and connecting wires from the PMT will be exposed beyond the Mu-metal casing.