Tagging Spectrometer Shift

Contents

Tagger Hodoscope

The tagger hodoscope consists of 218 scintillator counters which are installed behind the focal plane of the tagger magnet. The light produced in each counter is detected using Hamamatsu R9800 PMTs which are instrumented with JLab's custom designed dividers and divider-based amplifiers. The PMTs are operated at around 950 V. The hodoscope will be used for tuning the orientation of the radiator crystal by measuring the photon beam energy spectrum. This procedure will require involvement of experts and will not be performed by shift crew members. During data taking, the hodoscope will be used to monitor the beam stability.

Routine operation

The shift crew will be monitoring the detector performance parameters such as the counter rate per channel and detector occupancies as part of the routine shift check list. Any hot or dead channels have to be recorded in the log file. If the average counter rate significantly deviates (the range will be specified for each shift) from the expected rate, an expert should be called. In the case an alarm system detects the PMT current trip, the PMT high-voltage will be shutoff. The crew should restore the voltage on the PMT using the GUI interface (see instructions below). If the problem persists the expert should be called.

Control and monitoring of the system is accomplished using the Hall D graphical user interfaces (GUI) to EPICS [1] [2]. A description of how to bring up the GUI screens can be found in Section Slow Controls.

Voltage Settings and Control

All PMT voltages and trip currents will be preset by the detector experts. The HV will be switched on by the shift crew by clicking on 'All HV' button on the GUI interface. If any of the bases fail to set their high voltage a non-expert will first retry clicking 'All HV'. If the problem persists the expert should be called.

The counters should not be used at rates over 4 MHz for long periods of time.

For GlueX production runs, low-energy TAGH counters should be switched off because of the counter rate limitation. HV configuration for runs at 350 nA beam current is:

TAGH_HV_ProductionSummer2020_350nA.snap

Interlocks

Expert personnel

The individuals responsible for checking that the Hodoscope is ready to take data and setting its operating parameters are shown in following table. Problems with normal operation of the hodoscope should be referred to those individuals and any changes to their settings must be approved by them. Additional experts may be trained by the system owner and their name and date added to this table.

| Name | Number | Date of qualification |

|---|---|---|

| Alexander Somov | (757) 269-5553 | May 20, 2014 |

| HV, technician on call (TBD) |

Tagger Microscope

The tagger microscope consists of an array of 102 x 5 scintillators which are installed on the tagger magnet focal plane and will be used to monitor the photon beam energy spectrum in the 'coherent peak' region.

Routine operation

The shift crew will be monitoring the detector performance parameters such as the counter rate per channel and detector occupancies as part of the routine shift check list. Any hot or dead channels have to be recorded in the log file. If the average counter rate significantly deviates (the range will be specified for each shift) from the expected rate, an expert should be called.

Control and monitoring of the system is accomplished using the Hall D graphical user interfaces (GUI) to EPICS [3] [4]. A description of how to bring up the GUI screens can be found in Section Slow Controls.

Voltage Settings and Control

For shift workers, follow these instructions for turning on/off the tagger microscope electronics voltages through the CSS interface.

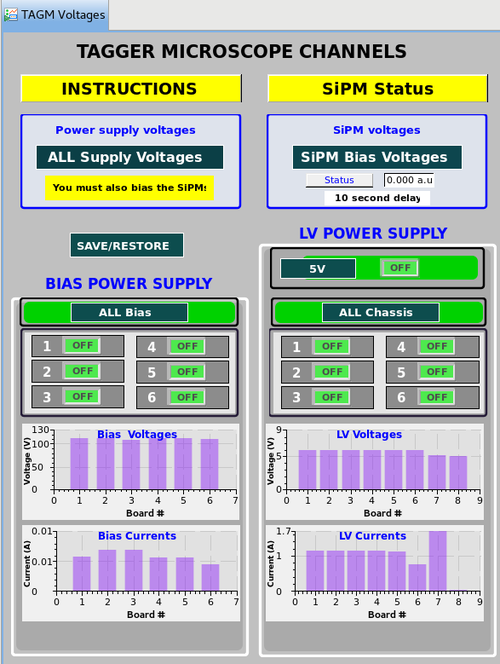

In the GlueX Overview CSS GUI, scroll down on the left side to the Tagger section and click TAGM Voltages. This will bring up a GUI like the one shown at the right, when everything is on. If any of the supplies are turned off, the green background behind the corresponding button should be red, and the corresponding bar graphs should be zeroed. There is a specific sequence to use for turning on and off the tagger microscope voltages. If you are on shift and you find things in an undefined state, first follow the steps for turning off the voltages and verify that they are off, then follow the sequence for turning them on from scratch. These instructions given below are the same as the ones displayed by the Instructions button at the top of the GUI.

- To turn on the tagger microscope voltages:

- Left-click the ALL Supply Voltages button, then select "Turn on all TAGM supply voltages" from the popup menu.

- Wait for all voltage buttons to turn green. Once the buttons turn green, they should display Off to indicate what will happen if you click them. Don't click them because you don't want to turn them off. At this point, the Bias Voltages should be around 110V and the LV Voltages between 5V and 6V as shown in the figure at the right. The LV currents should also look similar to those shown at the right. However, the Bias Currents should be near zero because you have not yet turned on the SiPM bias voltages.

- Left-click the SiPM Bias Voltages button, then select "ALL SIPMs LOW" from the popup menu.

- Wait for the bias currents bar graph to display non-zero currents, as an indication that the bias voltages have been enabled to the SiPMs. The y axis label on the Bias Currents graph is confusing; the first label should read 0.005 but this gets rounded up to 0.01 for some reason. Without beam in the hall, each of the 6 supplies should draw between 5mA and 10mA of current when fully biased. Board #6 only has 60 SiPMs on it instead of 90, so it should draw 2/3 of the current seen in the other 5 when fully biased.

- To turn off the tagger microscope voltages:

- Left-click the SiPM Bias Voltages button, then select "ALL SIPMs OFF" from the popup menu.

- Wait for the bias currents displayed in the bar graph to drop to zero, while all voltages remain on. This means that the SiPMs are no longer biased, but all of the front-end electronics is still on.

- Left-click the ALL Supply Voltages button, then select "Turn off all TAGM supply voltages" from the popup menu.

- Wait for all of the displayed bar graphs to drop to zero, and the supply status buttons to change from green to red. When this is complete, the TAGM electronics have been completely powered down.

Note 1: "ALL ON" should first turn on the bias power supply and then the LV power supplies. "ALL OFF" should first turn off the LV power supplies before turning off the bias power supply. This sequence is guaranteed if you follow the steps above in the order given.

Note 2: Various expert screens can be displayed by selecting other options from the menus built into this TAGM Voltages gui. It is safe to display any of these screens, but non-experts should not make any changes to parameters. Shift workers SHOULD NOT click the Save/Restore button on this gui, nor click any of the on/off buttons for individual channels, nor change current limits, nor otherwise mess with the supply voltages configuration, unless directed to do so by an expert.

Expert personnel

The individuals responsible for checking that the microscope is ready to take data and setting its operating parameters are shown in following table. Problems with normal operation of the microscope should be referred to those individuals and any changes to their settings must be approved by them. Additional experts may be trained by the system owner and their name and date added to this table.

| Name | Number | Date of qualification |

|---|---|---|

| Richard Jones (UConn) | (860) 377-5224 | May 20, 2014 |

| Alexander Somov | (757) 269-5553 | May 20, 2014 |