Difference between revisions of "Forward Multi-Wire Proportional Chambers Shift"

(→The Multi-Wire Proportional Chambers) |

(→Expert personnel) |

||

| (36 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | |||

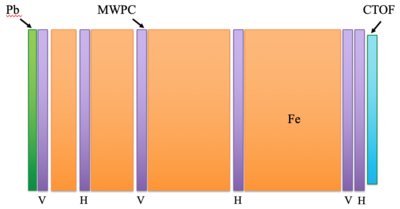

| − | + | [[Image:Muon detector sketch.png | thumb | 400px | Fig. 1. Sketch of muon detector. ]] | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | In this section we combine the information about the FMWPCs and the CTOF, as they together form the active detectors for the Hall D muon detector. In addition a common GUI was developed for both due to the small number of scintillator channels. A sketch of the muon detector is shown in Fig. 1. | |

| − | + | ||

| − | + | ||

| − | the | + | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | The | + | == The Multi-Wire Proportional Chambers (FMWPC) == |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | The Forward Multi-Wire Proportional Chamber (FMWPC) system consists of six planes interspersed between iron absorbers, which are located downstream of the FCAL on the downstream platform. Three chambers have vertical wires and three have horizontal wires. Each plane consists of 144 sense wires, operating at the nominal +1800 V. The preamps, located on the chambers are powered with +/- 5 V. The table provides a summary of the basic chamber properties. Additional details can be found in the [https://halldweb.jlab.org/DocDB/0050/005080/001/MWPC_writeup_for_ERR.pdf MWPC Construction Report]. | |

| + | |||

| + | {| class="wikitable" style="text-align: left;" | ||

| + | |+ MWPC Characteristics | ||

| + | |- | ||

| + | ! Parameter !! Value | ||

| + | |- | ||

| + | | style="text-align:left" | sensitive area || 60 x 60 inch2 | ||

| + | |- | ||

| + | | style="text-align:left" | sense wire pitch || 0.4 inch | ||

| + | |- | ||

| + | | style="text-align:left" |wire plane to cathode plane distance || 0.4 inch | ||

| + | |- | ||

| + | | style="text-align:left" |size of central deadened region || 10 x 10 cm2 | ||

| + | |- | ||

| + | | style="text-align:left" |wire arrangement || planar, with field wires between sense wires | ||

| + | |- | ||

| + | | style="text-align:left" | sense wire diameter || 20 um | ||

| + | |- | ||

| + | | style="text-align:left" | field wire diameter || .003” non-central region, .004” central region | ||

| + | |- | ||

| + | | style="text-align:left" | sense wire voltage || typically +1800 Volt | ||

| + | |- | ||

| + | | style="text-align:left" | field wire voltage || ground | ||

| + | |- | ||

| + | | style="text-align:left" | cathode plane voltage || ground | ||

| + | |- | ||

| + | | style="text-align:left" | operating gas || 90:10 argon:CO2 by volume, flowing at 5 cc/s | ||

| + | |- | ||

| + | | style="text-align:left" | typical chamber gain || about 100,000 | ||

| + | |- | ||

| + | | style="text-align:left" | maximum drift time || about 570 ns | ||

| + | |- | ||

| + | | style="text-align:left" | number of electronic channels per chamber || 144 | ||

| + | |} | ||

| + | |||

| + | == Central Time-of-Flight (CTOF) == | ||

| + | |||

| + | The Central Time-of-Flight system consists of a single plane of plastics scintillators located downstream of the last FMWPC. The plane consists of four scintillators hung vertically, placed symmetrically relative to the beamline, two on each side. Each counter consists of an active scintillator area of 1.27x20x120 cm3 with light guides on top and bottom connected to XP2262B pmts. The typical voltage is -1700 V. Each of the eight pmts has two outputs, supplying signals to the FADC250s and discriminators that feed CAEN TDCs, scalers and trigger logic that generate the Front-Panel CTOF trigger. The CTOF trigger consists of a logic AND of top and bottom pmts for each counter and a logic OR of the four counter coincidences. | ||

== Routine operation== | == Routine operation== | ||

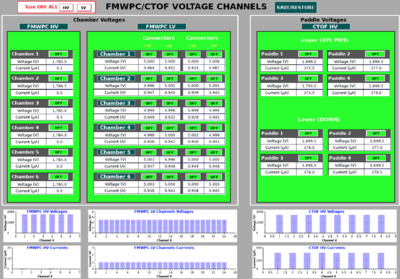

| − | [[Image:FMWPC_epics_screen.png | thumb | 400px | Fig. | + | [[Image:FMWPC_epics_screen.png | thumb | 400px | Fig. 2. FMWPC HV, LV GUI panel. ]] |

| − | The most important task for the shift workers is to monitor the parameters (using GUIs) and report any changes from the normal operation for the | + | The most important task for the shift workers is to monitor the parameters (using GUIs) and report any changes from the normal operation for the HV and LV of the FMWPC and CTOF systems. Both systems are controlled using a single GUI. A description of how to bring up the corresponding GUI screens and how to operate them can be found in the[[Slow Controls Shift| Section Slow Controls]]. The HV and LV subsystems have a common GUI. The GUIs are designed to show green color if all the parameters in a certain subsystem/subgroup are within their operating limits. If any of the parameters is out of limits the background for the corresponding subsystem/subgroup will turn red. An example the GUI is shown in Figs. 2 for normal operating conditions. |

| − | The shift workers are allowed, using the GUI, to turn ON and OFF all the HV and LV | + | The shift workers are allowed, using the GUI, to turn ON and OFF all the HV and LV systems, as well as parts of them or the individual channels. Instructions how to do this are given in [[Slow Controls Shift| Section Slow Controls]], but the general rule is either to bring the pop-up menu with left click on the group title (like "ALL OFF ALL HV / LV") or to click on the individual channel knob (the knob title shows the action to be taken after pressing it). For example, in case a HV channel trips, one should press the corresponding channel knob once (acknowledging the trip) and then again to turn it on. The corresponding voltage parameters, like ramp up/down rates, trip currents, set voltage values etc. should not be changed by the shift workers. The restoration of voltage settings to nominal operation can be accomplished using the top right button "SAVE/RESTORE." |

| − | + | The FMWPCs operate with pre-mixed 90/10 Ar/CO2 bottles located in the gas racks outside the hall. The gas flow to each plane is controlled via manually adjustable flow meters located on each chamber. The flow rate will be set at the beginning of the run by experts, but the flow rate can be viewed remotely by either the east wall "halldcam3" or the south wall "south-cam" cameras. For instructions how to operate the camera, refer to [[Slow Controls Shift| Section Slow Controls]]. The shift the workers should record the gas flow for each chamber once per shift. | |

'''Operations beyond what is specified above shall only be performed by the system expert or under his/her direction'''. | '''Operations beyond what is specified above shall only be performed by the system expert or under his/her direction'''. | ||

| Line 37: | Line 60: | ||

== Interlocks== | == Interlocks== | ||

| − | + | The HV and LV modules are set to immediately turn off the voltage if the current exceeds the corresponding limit. Setting the voltage channel back should be done only manually by the operator. | |

== Expert personnel == | == Expert personnel == | ||

| − | The individuals responsible for the operation of the | + | The individuals responsible for the operation of the FMWPCs are shown in the following table. |

Problems with normal operation of the FDC should be referred to those individuals and any changes to their settings must be | Problems with normal operation of the FDC should be referred to those individuals and any changes to their settings must be | ||

approved by them. Additional experts may be trained by the system owner and their name and date added to this table. | approved by them. Additional experts may be trained by the system owner and their name and date added to this table. | ||

{| border=1 | {| border=1 | ||

| − | |+ Table: Expert personnel for the | + | |+ Table: Expert personnel for the FMWPC and CTOF systems |

|- bgcolor=#DFDFDF | |- bgcolor=#DFDFDF | ||

! width=200px | Name !! width=100px | Extension !! Date of qualification | ! width=200px | Name !! width=100px | Extension !! Date of qualification | ||

|- | |- | ||

| − | | | + | | Beni Zihlmann || align=center | 269-5310 || align=center | May 20, 2022 |

| + | |- | ||

| + | | Rory Miskimen || align=center | 413-824-6293 || align=center | May 20, 2022 | ||

|} | |} | ||

Latest revision as of 14:36, 11 May 2022

In this section we combine the information about the FMWPCs and the CTOF, as they together form the active detectors for the Hall D muon detector. In addition a common GUI was developed for both due to the small number of scintillator channels. A sketch of the muon detector is shown in Fig. 1.

Contents

The Multi-Wire Proportional Chambers (FMWPC)

The Forward Multi-Wire Proportional Chamber (FMWPC) system consists of six planes interspersed between iron absorbers, which are located downstream of the FCAL on the downstream platform. Three chambers have vertical wires and three have horizontal wires. Each plane consists of 144 sense wires, operating at the nominal +1800 V. The preamps, located on the chambers are powered with +/- 5 V. The table provides a summary of the basic chamber properties. Additional details can be found in the MWPC Construction Report.

| Parameter | Value |

|---|---|

| sensitive area | 60 x 60 inch2 |

| sense wire pitch | 0.4 inch |

| wire plane to cathode plane distance | 0.4 inch |

| size of central deadened region | 10 x 10 cm2 |

| wire arrangement | planar, with field wires between sense wires |

| sense wire diameter | 20 um |

| field wire diameter | .003” non-central region, .004” central region |

| sense wire voltage | typically +1800 Volt |

| field wire voltage | ground |

| cathode plane voltage | ground |

| operating gas | 90:10 argon:CO2 by volume, flowing at 5 cc/s |

| typical chamber gain | about 100,000 |

| maximum drift time | about 570 ns |

| number of electronic channels per chamber | 144 |

Central Time-of-Flight (CTOF)

The Central Time-of-Flight system consists of a single plane of plastics scintillators located downstream of the last FMWPC. The plane consists of four scintillators hung vertically, placed symmetrically relative to the beamline, two on each side. Each counter consists of an active scintillator area of 1.27x20x120 cm3 with light guides on top and bottom connected to XP2262B pmts. The typical voltage is -1700 V. Each of the eight pmts has two outputs, supplying signals to the FADC250s and discriminators that feed CAEN TDCs, scalers and trigger logic that generate the Front-Panel CTOF trigger. The CTOF trigger consists of a logic AND of top and bottom pmts for each counter and a logic OR of the four counter coincidences.

Routine operation

The most important task for the shift workers is to monitor the parameters (using GUIs) and report any changes from the normal operation for the HV and LV of the FMWPC and CTOF systems. Both systems are controlled using a single GUI. A description of how to bring up the corresponding GUI screens and how to operate them can be found in the Section Slow Controls. The HV and LV subsystems have a common GUI. The GUIs are designed to show green color if all the parameters in a certain subsystem/subgroup are within their operating limits. If any of the parameters is out of limits the background for the corresponding subsystem/subgroup will turn red. An example the GUI is shown in Figs. 2 for normal operating conditions.

The shift workers are allowed, using the GUI, to turn ON and OFF all the HV and LV systems, as well as parts of them or the individual channels. Instructions how to do this are given in Section Slow Controls, but the general rule is either to bring the pop-up menu with left click on the group title (like "ALL OFF ALL HV / LV") or to click on the individual channel knob (the knob title shows the action to be taken after pressing it). For example, in case a HV channel trips, one should press the corresponding channel knob once (acknowledging the trip) and then again to turn it on. The corresponding voltage parameters, like ramp up/down rates, trip currents, set voltage values etc. should not be changed by the shift workers. The restoration of voltage settings to nominal operation can be accomplished using the top right button "SAVE/RESTORE."

The FMWPCs operate with pre-mixed 90/10 Ar/CO2 bottles located in the gas racks outside the hall. The gas flow to each plane is controlled via manually adjustable flow meters located on each chamber. The flow rate will be set at the beginning of the run by experts, but the flow rate can be viewed remotely by either the east wall "halldcam3" or the south wall "south-cam" cameras. For instructions how to operate the camera, refer to Section Slow Controls. The shift the workers should record the gas flow for each chamber once per shift.

Operations beyond what is specified above shall only be performed by the system expert or under his/her direction.

Interlocks

The HV and LV modules are set to immediately turn off the voltage if the current exceeds the corresponding limit. Setting the voltage channel back should be done only manually by the operator.

Expert personnel

The individuals responsible for the operation of the FMWPCs are shown in the following table. Problems with normal operation of the FDC should be referred to those individuals and any changes to their settings must be approved by them. Additional experts may be trained by the system owner and their name and date added to this table.

| Name | Extension | Date of qualification |

|---|---|---|

| Beni Zihlmann | 269-5310 | May 20, 2022 |

| Rory Miskimen | 413-824-6293 | May 20, 2022 |