Solenoid Coil Test in Test Lab

From GlueXWiki

Notes and To-Do lists for the 2009/2010/2011 solenoid coil tests

Contents

Meetings

Things To Do

Solenoid and Individual Coil Tests

- HDSOLENOID Full solenoid test electronic logbook (can access old coil test log via the HDCOILTEST elog category)

-

HDCOILTEST Individual coil test electronic log book (may stop working one day) (from on-site) -

HDCOILTEST Individual coil test electronic log book (may stop working one day) (from off-site)

-

-

Controls screensnot working - HDList

- Access HMI screens through VNC

OSP

- All OSP docs reside in M:\halld\Solenoid\CoilTest\OSP

Project Milestones

- Solenoid Test Milestones, 12 GeV milestones to be tracked by project management office.

- obsolete at this point, given all the additional work required, lack of manpower, and the many delays

FastTrack

- FastTrack solenoid schedules are in M:/halld/solenoid/FastTrack Schedules.

System Diagrams and Related Documents

- George put these in M:/halld/solenoid/Controls.

Test Area

- Notes:

- Area in the test lab is 20'6" x 25'9", currently filled with coils and coil parts.

- Bob Bennett is Test Lab "space czar."

- Wayne is designing overall layout.

- Will use SRF storage area for large power supply (6' x 5', 5' H, 5000 lbs) and switch (QWeak area unavailable).

- Must maintain clear areas around racks and power supply, and cannot block pedestrian walkways.

- Platform is 172" x 160", cryo can will sit on top.

- Platform must be removed to swap coils, and all connections to it must be broken.

- Area has two 25T cranes, but need both (and strongback) to lift heaviest pieces (up to 45 tons).

- Only a few dual-crane lifts needed.

- Need come-alongs and anchors to move yokes and coils along rails.

- Some areas will need to be roped off due to high B fields (5 G for pacemakers; other limits 60 G 8-hr body, 600 G 8-hr limb).

- May need to remove some fences.

- Magnet forces: 5 kG == 1 Atm, scales as square of B field.

- When done, may leave infrastructure in place for magnet tests for other halls.

- Coil center located 1/3 of the way along the long axis of our test area.

- When saturated low field regions extend fairly uniformly around coil center in all directions. When not saturated low field regions extend out mainly along coil axis.

- Will be able to use QWeak area for staging, coil repairs (29-Oct-2009).

- To Do:

- Determine areas to be roped off due to high B field - Jennifer Williams

- Done:

- Enable building access for everyone - Elliott - done 19-Jun-2009 (same requirements as access to Cebaf Center)

- Look into getting space in adjacent areas - George - done 2-Jul-2009

- Distribute Floyd's B field map for single coil, no cladding, fine scale - George - done 9-Jul-2009

- Determine location of all components - Wayne - done 29-Jul-2009

- Determine how far cranes must be apart for dual-lift - George - done 29-Jul-2009

- Order yoke strongback - George - done 27-Aug-2009

- Investigate sensitivity of electronic equipment to B fields - Elliott

- Seems not to be a problem - 1-Dec-2009

Infrastructure

- Notes:

- Platform borrowed from Hall A.

- Must be moved to replace coils, 4-point lift.

- Rails and transportainer currently at IU.

- Have or can borrow all material moving equipment, or will contract out to rigging firm.

- Have or can borrow all tools needed.

- Controls racks coming from from computer center.

- Need 60 W liquid He, Test Lab supply capable of 500 W, but share with Cryo group.

- Must account for magnetic forces on all structures, perhaps as much as 20-30 Gauss static B field.

- Electrical cables must be untouchable to 8 feet above floor.

- Power supply is Danfysik MPS 854 system 8000 w/power input of 480VAC at 91Amps.

- Power supplies requires 190 liters/min max at max 174psi, minimum differential pressure 43psi.

- Found electrical switch so don't have to order one.

- LN2 can relocated to platform so that we can use short U-tubes.

- Test lab cryo can supply 3 g/s He.

- Contact for cryogen supply in the Test Lab is Pete Kushnick.

- To Do:

- Done

- Design structures and mechanical components, route cables, etc. - Wayne - done 29-Jul-2009

- Get three racks from CC - Elliott, Tom - done 26-Oct-2009

- Determine cryogen supply/return needs - George - done 26-Oct-2009

- Arrange for cryogen supply/return with Dana Arenius (and Kelly Dixon?)- Tom - done 26-Oct-2009

- Produce construction/installation sequence - Chuck

- Retrieve jack stands and rails from IUCF - Chuck

- Retrieve transportainer from IUCF - Chuck

- Install power supply cooling equipment, etc. - Tom

- Arrange for electrical infrastructure installation - Tom

Components

- Platform

- Entire platform and supports will be moved when changing coils.

- Must account for magnetic forces.

- Ladder needs to be shortened and straightened.

- Must include cable trays and strain relief, especially for power connections.

- Rails

- Currently in transportainer at IU, George will have a look when he goes out there.

- Cryo, U-tubes, can and heat exchanger

- Bids in for cryo can, no contract or delivery date yet.

- Heat exchanger from Hall A.

- By moving LN2 can will not need to order U-tubes.

- Will use Anaconda and borrowed short U-tubes.

- Piping

- Not clear where N2 vent will be routed.

- Must incorporate drip pan under N2 vent due to icing.

- May be ODH considerations.

- Electrical power

- Need to work out where outlets are needed.

- Power supply

- Resides in Physics Storage bldg.

- Uses 3-phase 480 V.

- 10V supply, 3000 A.

- Integral dump resistor, must bypass reversing switch when wiring to magnet.

- Need switch nearby.(c** Look into possibility of locating computer in control room

- Cables not water-cooled. 1.5" diameter cables, 1" copper.

- Coils, rings and yokes

- Buttresses are needed in coil 2.

- Yoke modifications are needed.

- Coil repairs will continue through summer 2009.

- All must be leak-tested again.

- Spacer rings designed in identical quadrants, two pieces per quadrant.

- Need to design yoke jack stands.

- Need to replace PVC-coated controls wiring in all four coils.

- Controls system

- Is anything sensitive to B fields?

- Will wire up as per final four-coil system.

- Own DIN-mount RS232 module, can borrow power supply and ControlNet module from Steve L.

- Not needed, will use Point I/O system for RS232 and Ethernet/IP communications adapter.

- Steve L has 75-Ohm quad-shield RG-6 cable and terminators for ControlNet wiring.

- Must be careful not to use 50-Ohm components in ControlNet system.

- Not clear where computer will be located.

- Should use high-quality color-coded terminal blocks.

- Should use color-coded wiring, different color schemes for different systems.

- We will not instrument any thermocouples, but added some Si diodes.

- Must use appropriate wire (phosphor-bronze?) and wire insulation (Formvar?).

- Do we need a redundant PLC system?

- Decision is yes since cost is relatively low and impact high.

- Need a backup computer for coil test.

- Decided to use one A-B chassis for two coils.

- Misc tools, tables, chairs, ladders, etc.

- What do we need? Can we beg, borrow, and/or steal?

- To Do:

- Reinforce coil 2 windings and replace wiring - George

- Complete IUCF coil 3 shield and wire replacement - George

- Replace wire in coil 4 - George

- Done

- Verify we can borrow heat exchanger from Hall A - Mark S - done 2-Jul-2009

- Determine if sensible to use one PLC chassis per coil - Mark S and Elliott - done 16-Jul-2009, yes!

- Verify all cryo transfer lines and U-tubes are available on site - Mark S - done 29-Jul-2009

- Situation changed 28-Aug-2009, may not be able to use Hall C U-tubes!

- Complete coil 2 stress analysis - George, Floyd - done 20-Aug-2009

- Borrow short U-tubes and Anaconda - Tom - done 26-Oct-2009

- Design and order magnet/yoke support components - George - done 29-Oct-2009

- Order magnet spacer rings - George - done 29-Oct-2009

- Arrange for yoke modifications - George - done 29-Oct-2009

- Verify copper/PVC wire will work at LN2 temperatures - Scot - done 1-Nov-2009

- Will replace all PVC-coated wire in all coils

- Create complete P&I diagram for Mark W - James, George - done 9-Dec-2009

- Modify control wiring diagrams - Mark S, Scot, Slava - done 9-Dec-2009

- Order A-B equipment - Elliott - done 14-Dec-2009

- Order other controls instrumentation - Scot - done 17-Dec-2009

- Modify power supply dump resistor wiring - Mark S. - done 7-Jan-2010

- Not needed, just need to bypass polarity reversing switch

- Order cryo can - George - done 7-Jan-2010

- Complete coil 1 repairs and wire replacement - George

- Design cryo/electrical interface to cryo can - Josh, James

- Design pressure relief system for cryostat testing - Josh

- Design and order vent and other piping - Tom

- Get heat exchanger from Hall A - Tom

- Ensure we have all tools needed - Tom

- Get backup controls computer - Elliott

Programming

- Notes:

- Mark W will do all programming.

- Can borrow lots of code from Steve Lassiter and co.

- Single computer will perform all control and monitoring tasks.

- Hall D P&I diagram will be the basis for control system design.

- P&I must include all vessels, valves, instrumentation, etc.

- Need min/max flow rates, delta-T's, strain gauge readings, etc.

- Have about one man-week of Steve Lassiter's time for consultation.

- IMPORTANT - power must be off to carbon composite resistors in He vessel when under vacuum or they will burn out!

- May use EWEB module to server controls data to web.

- To Do:

- Done

- Install new memory in controls computer - Elliott and Mark W - done 6-Jul-2009

- Borrow code from Steve Lassiter - Mark W - done 9-Jul-2009

- Purchase new software licenses - Elliott - done 16-Jul-2009 none needed thanks to Steve Lassiter

- Install all software on controls computer - Mark W - done 16-Jul-2009

- Renew software update/maintenance contract - Elliott - done 27-Aug-2009

- Update all software to latest version - Mark W - done 9-Sep-2009

- Set up in test rack in ARC 101 - Mark W - done 15-Sep-2009

- Explain overall control strategy to Mark W - George, Mark S, Scot - done 9-Dec-2009

- Determine min/max flow rates, delta-T's, strain gauge values, etc. - George

- Determine what needs to be archived and how often - George

- Set up controls hardware in F117 - Armen, Scot, Mark S, Mark W and Elliott

- Design and implement full control and archiving system - Mark W

- Work with Steve Lassiter as appropriate.

Staging

- Notes:

- Will instrument controls racks in F117, then move to Test Lab.

- Armen (Electronics group) will help with wiring in F117.

- Will instrument for final 4-coil system.

- To Do:

- Done

- Get and move 3 racks into F117 - Tom, Elliott - done 26-Oct-2009

- Verify adequate staging areas available in Test Lab - Tom - done 29-Oct-2009

- Rearrange F117 - Scot, Mark S - done 17-Dec-2009

Reviews

- Notes:

- Bob May and Paul Collins are contacts with EHS&Q for safety documentation and reviews

- Need cryo, electrical, mechanical, and operations reviews.

- Suresh Chandra responsible for structural review new platform and related components; will use outside consultant.

- There will be a magnet review in Nov 2009.

- To Do:

- Done

- Mini-review of PLC vendor choice (Report from Omar Garza and Jonathan Creel) - done 15-Jun-2009

- Write thank-you letter to Jonathan Creel and Omar Garza for participating in PLC vendor review - Elliott - done 24-Jun-2009

- Contact EH&S group concerning documentation and reviews - Elliott - done 29-Jun-2009

- Write appropriate documentation - George, Mark S, Tom, Elliott

- Set up all reviews - George, Elliott

Construction

- Notes:

- What training do we all need?

- To Do:

- Done

- Get appropriate training - All

- Arrange for telephone and networking in test area - Elliott

- Move controls racks to Test Lab - Mark S, Tom

- Move computer to Test Lab - Mark W and Elliott

- Install all components - Mark S, Tom, Scot

- Hook up controls system - Mark S, Scot, Mark W and Elliott

- Verify operation of control/archiving system - Mark W, Mark S, Scot, George and Elliott

Coil Tests

- Notes:

- Purpose:

- Verify correct operation of all coils.

- Measure coil strains up to full current (1600 A).

- Will take about six weeks per coil to install, cool down and test.

- Only about 1 day of actual measurements per coil.

- Nitrogen usage for the 300-80 K cooldown is ~18 to 21 g/s

- 300-80 K cooldown: ~7 to 11 days

- 80-4 K cooldown: ~2 to 4 days

- Purpose:

- Done

- Install electronic logbook system - Elliott - done 20-Aug-2009

- Test plan for Coil 1

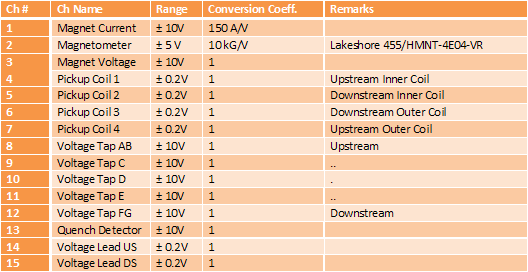

- Fast DAQ Channel List

- Connection for Coil 3

- Chan 21: Pickup 1

- Chan 23: Pickup 2

- Chan 25: Pickup 3

- Chan 27: Pickup 4

- Chan 13: Coil D1

- Chan 11: Coil D2

- Chan 15: Coil A

- Chan 7: Coil BC

- Chan 5: Field Probe O2

- Chan 31: Field Probe O3 (conditioned, delay)

- Chan 19: MPS current

- Chan 1: MPS voltage

- Connection for Coil 2

- Chan 21: Pickup 1

- Chan 23: Pickup 2

- Chan 25: Pickup 3

- Chan 27: Pickup 4

- Chan 7: Coil C

- Chan 13: Coil D

- Chan 9: Coil A

- Chan 15: Coil B

- Chan 5: Field Probe O2

- Chan 31: Field Probe O3 (conditioned, delay)

- Chan 19: MPS current

- Chan 1: MPS voltage